- VADODARA, GUJARAT

- GST NO. : 24CJHPB4514L1ZE

+91-8128882975 Call / WhatsApp |

View Mobile Number Call Us |

rameshsteelandalloys@gmail.com Drop us a line |

| Business Type | Exporter, Supplier, Importer |

Scope :

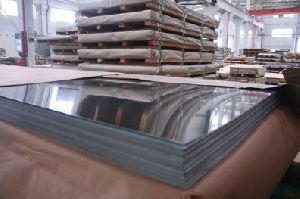

COR-TEN A applies to plates up to 12.5mm in thickness, COR-TEN B applies to plates up to 50mm in thickness.

Definition :

Weathering means that due to their chemical compositions COR-TEN A and COR-TEN B steels, when utilized unprotected, exhibits increased resistance to atmospheric corrosion compared to unalloyed steels. This is because it forms a protective layer on its surface under the influence of the weather.

Applications

: The steel is used for various types of welded, bolted and riveted constructions e.g. steel frame structures, bridges, tanks and containers, exhaust systems, vehicles and equipment constructions.

Basic guidelines for the use of this steel in the unprotected condition are described in EN 10025-5 and DASt rule 007.

In order to obtain fine grain structure a sufficient amount of nitrogen absorbing elements is added (e.g. ≥0.02% Al).

Mechanical Properties, in the state of delivery condition

At room temperature for plates ≥3mm in thickness (transverse test specimans, according to EN 10002). Requirements to hot rolled plates ≤3mm in thickness according to EN 10025-5.

Mpa = 1N/mm2

In case of cold rolled material the yield point is min. 310 Mpa and the tensile strength min. 445 MPa. Furthermore cold rolled sheets ≤3mm in thickness made of steel grade COR-TEN A-F for increased demand to the cold formability is available.

Mechanical properties:

Yield point min. 275 Mpa

Tensile strength min. 410 Mpa

elongation min. 25%

Tolerances on dimensions and shape according to EN 10131.

1 Mpa = 1N/mm2

The notched-bar impact energy is determined on ISO-V longitudinal test specimens at a temperature of - 20°C as an average of three tests. For product thicknesses ≥10mm the average value is at least 27 J. For thicknesses between 10mm and 6mm, the minimum impact value is reduced proportionally to the specimen width (product thickness).

Number of Tests

1 tensile test

1 test specimen per 40 t from each heat*)

Notched bar impact test

1 set specimens per 40 t from each heat *)

(3 specimens) (at test temperature -20°C)

MATERIALS WHICH CAN BE SUPPLIED IMMEDAITELY OR WITH SHORT DELIVERY PERIOD ARE AS PER BELOW MENTIONED SPECIFICATION

COR-TEN® A, COR-TEN®A, COR-TEN A, CORTEN-A, CORTEN A

COR-TEN® B, COR-TEN®B, COR-TEN B, CORTEN-B, CORTEN B

ASTM A588 GR. A, ASTM A 588 GR.A, ASTM A588 GR.A, ASTM A 588 GR. A,

EN-10025-5 S355J2W, EN10025 S 355 J2W, EN-10025 S355J2W

S355J2G1W EN10155, S 355 J2G1W EN-10155, S355J2G1W EN-10155

Chemical Composition (heat analysis, %)

| Grade | C | Si | Mn | P | S | Cr | Cu | V | Ni |

| COR-TEN A | 0.12 | 0.25-0.75 | 0.20-0.50 | 0.07-0.15 | 0.03 | 0.50-1.25 | 0.25-0.55 | - | 0.65 |

| COR-TEN B | 0.16 | 0.30-0.50 | 0.80-1.25 | 0.03 | 0.03 | 0.40-0.65 | 0.25-0.40 | 0.02-0.10 | 0.4 |

Mechanical Properties

| Grade | Minimum yield point (ReH Mpa *) | Tensile strength Rm MPa | Minimum elongation A (Lo=5.65 √So) % |

| COR-TEN A | 355 | 470-630 | 20 |

Specification

| Grade | Material thickness mm | Minimum yield point (ReH Mpa *) | Tensile strength Rm MPa | Minimum elongation A (Lo=5.65 √So) % |

| COR-TEN B | ≤16 | 355 | 470-630 | 20 |

EQUIVALENT SPECIFICATIONS

| Material # | EN 10155 | SEW 087 | NFA 35-502 | UNI | BS 4360 | UNE | ASTM | JIS G3114 |

| 8961 | S235J2W | WTSt 37-3 | E 24 W 4 | Fe 360 DK 1 | - | - | - | - |

| 8945 | S355J0WP | E 36 WA 3 | Fe 510 C1K1 | WR 50 A | - | - | - | - |

| 8946 | S355J2WP | - | E 36 WA 4 | Fe 510 D1K1 | - | - | A 242 Type 1 | - |

| 8959 | S355J0W | - | E 36 WB 3 | Fe 510 C2K1 | WR 50 B | - | A 588 - A 242 Gr. 1 | SMA 50 AW |

| 8963 | S355J2G1W | WTSt 52-3 | - | Fe 510 D2K1 | WR 50 C | - | A 588 Gr. A | to |

| 8965 | S355J2G2W | - | - | - | - | - | - | SMA 50 CP |

| 8966 | S355K2G1W | - | E 36 WB 4 | - | - | - | A 709 Gr. 50 W | - |

| 8967 | S355K2G2W | - | - | - | - | - | - | - |

Looking for "Weather Resistant Plate" ?

Explore More Products